Platinum, Gold, Silver Jewelry Casting Machine

MADE IN JAPAN

We were interviewed by

a Japanese TV program.

Jewelry

Casting series

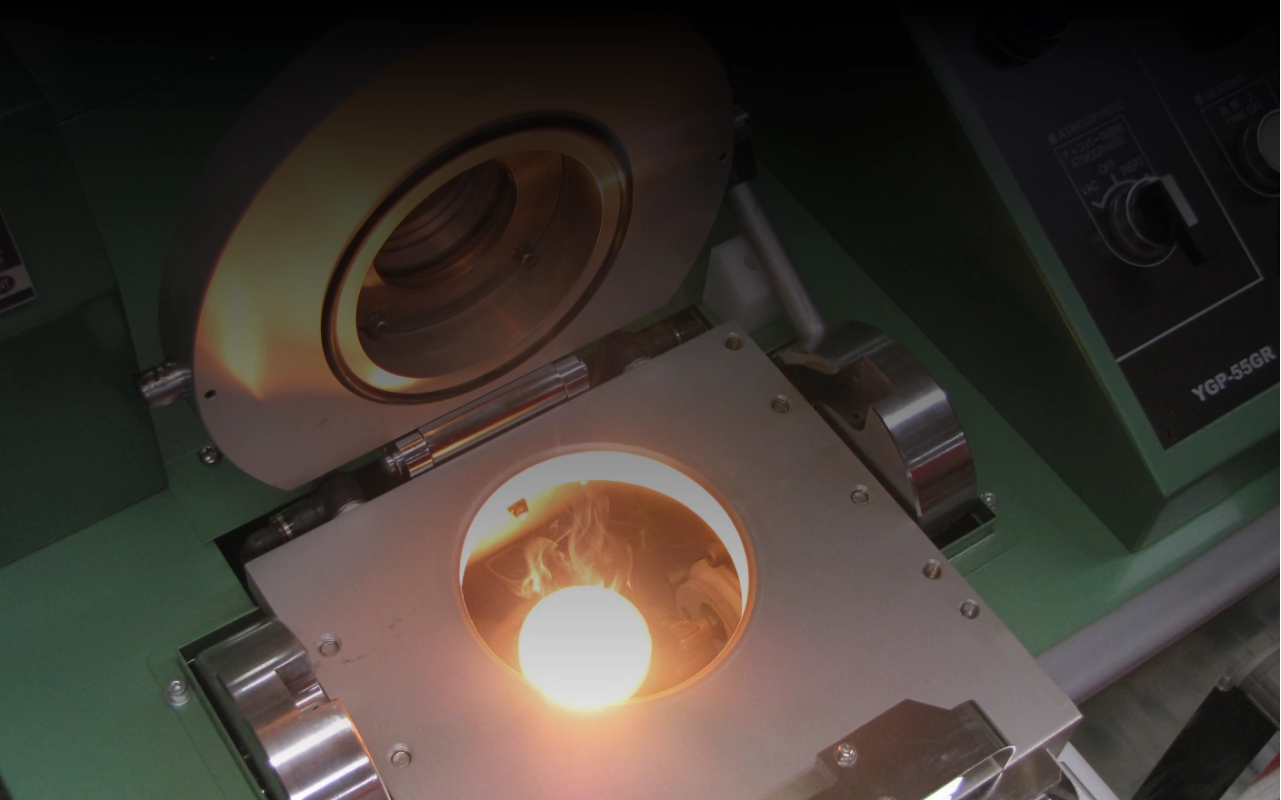

Platinum Casting

Bench-top pressure casting machine with the mold-rotation system (patent).

Best suited for prototyping or/and small-lot production.

High-performance casting machine ideal for production of one-off jewelry

Gold/Silver Casting

A vacuum/pressure casting machine for metals with melting point up to 1200C(2200F)

Digital sequence / fully automatic operation (semi-automatic, manual mode can be selective) among selective 3 casting method (solo-vacuum / solo-pressure / vacuum pressure).

High-repeatability can be secured due to memory data.

Titanium Casting

Titanium is considered difficult metal to cast. However, with an understanding of titanium's properties and the right casting machine, the fabrication of titanium products is within your grasp.

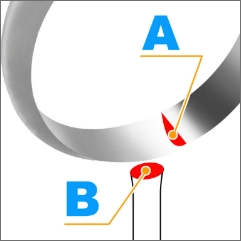

Centrifugal Casting Machine YC Series

The YC series centrifugal casting machines have excellent casting ability, especially for filigrees and delicate designs. Compared to other casting methods, the efficient displacement of molten metal and internal gas allows molten metal to feed instantly to the edge of the castings.

Original Jewelry Investment Powder

100% silica ready-mix investment powders of different particle sizes, mixed with a unique, historically proven recipe, and have been the choice of users in Japan, a country known for its strict quality standards, since 1966. ALL investment powder is resulting in a casting surface of a higher rank.

For details

About Us

Yoshida Cast Industry Co., Ltd. is Japan's oldest lost-wax casting machine manufacturer, founded in 1960. The company also develops and sells various consumables and equipment for casting and metal melting for making ingots, shots, industrial test pieces, spattering targets. Ferro alloys (master alloys) and so on.

Today, we manufacture and sell analog and digital casting machines and Induction / arc melting furnaces for not only precious metals but also various non-precious metals and alloys, and provides equipment and consumable materials to companies in all industries as well as the jewelry industry.

PEOPLE CHOSE US

We are the oldest casting machine manufacturer in Japan,

having developed and launched the first Japanese-made jewelry casting machine in 1960.

-

Over 60 years of

history and achievements -

PIONEER

in jewelry casting machines -

Not only selling machines

GENEROUS TECHNICAL SUPPORT -

From selection of peripheral equipment and materials to after-sales follow-up

ONE-STOP SERVICE

TECH INFO

Introduction and information on basic knowledge about casting and metal melting

Contact

Please feel free to contact us with any questions, consultations.

+81-048-662-7730

CONTACT US