★This column is a commentary on lost wax casting with a block molding method

This column has been presented by Yoshida Cast

Casting defects come in various forms, such as cracks in castings, surface roughness and porosity and so on.

Casting defects are classified into several types. And each of these has different causes.

In addition, since the casting process is diverse, the cause may not always be one, and most cases are complicated.

Typical failures are roughly classified into six categories.

Fifth, let's take a look at the causes and countermeasures for "porosity".

[toc]

What is a porosity?

Porosity is a phenomenon in which cavity(s) occurs inside castings it is one of the representative casting defects.

Sometimes porosity is called blowhole or/and cavity in other industries.

Why do Porosities take place? And what is countermeasure.?

Porosity can be caused by a variety of reasons such as too high or too low casting metal temperature or internal gas.

At the time porosities happens, it is necessary to review attaching condition of gate sprues and entire casting conditions, especially temperature.

In some cases, porosities may be created by property of casting alloy itself.

Although it will be technical, if possible, it is also necessary to confirm solid and liquid phases in a phase diagram of corresponding alloy.

Here are four main causes of porosities and how to overcome them.

1 Gas Porosities

Gas porosities occur when gas remains inside a casting metal due to excess gas contained in casting metal or/and substitution between internal gas and pouring metal does not performed smoothly during casting.

Degassing of casting metal before casting or forced degassing during melting may be required sometimes.

In some cases, it would be necessary to check burn-out cycle for furnaces in order to confirm there is no residue in casting molds.

General Gas Porosity (Blowholes) (Pt)

General Gas Porosity (Au)

a mark of a large amount of gas

Cross-sectional image of gas porosities

The appearance differs depending on conditions such as type of metal and amount of gas. Generally speaking, inside of gas porosities are in a state close to mirror surface.

Reflection of light may be observed with a microscope.

CAUSE 1 / Internal gas

There is a case casting metal itself may contain gas.

When reusing buttons that has been used for casting once more, if investment powder adheres to the buttons, the investment powder (gypsum component) will thermally decompose and generate gas. Thoroughly wash away investment powder adhering with an ultrasonic cleaner.

Even virgin metal may contain gas. Precious metal is guaranteed purity when it is sold but not guaranteed to be free of inclusions that would adversely affect casting. In other words, new metal doesn't mean it doesn't have gas.

It is possible to forcibly expel gas with adding deoxidizers such as zinc, silicon, and phosphorus into the melted metal. Deoxidizing material should be put in from 1/1000 to 2/1000 (weight ratio) of the dissolved amount of metal. Stir well the melted metal containing deoxidizer.

When borax is desired to use, never add borax first but after degassing process.

If you don't want to mix the deoxidizing agent into casting metal, solidify melted casting metal into a rod shape and beat or stretch the ingot with a roller or hammer to physically remove internal gas.

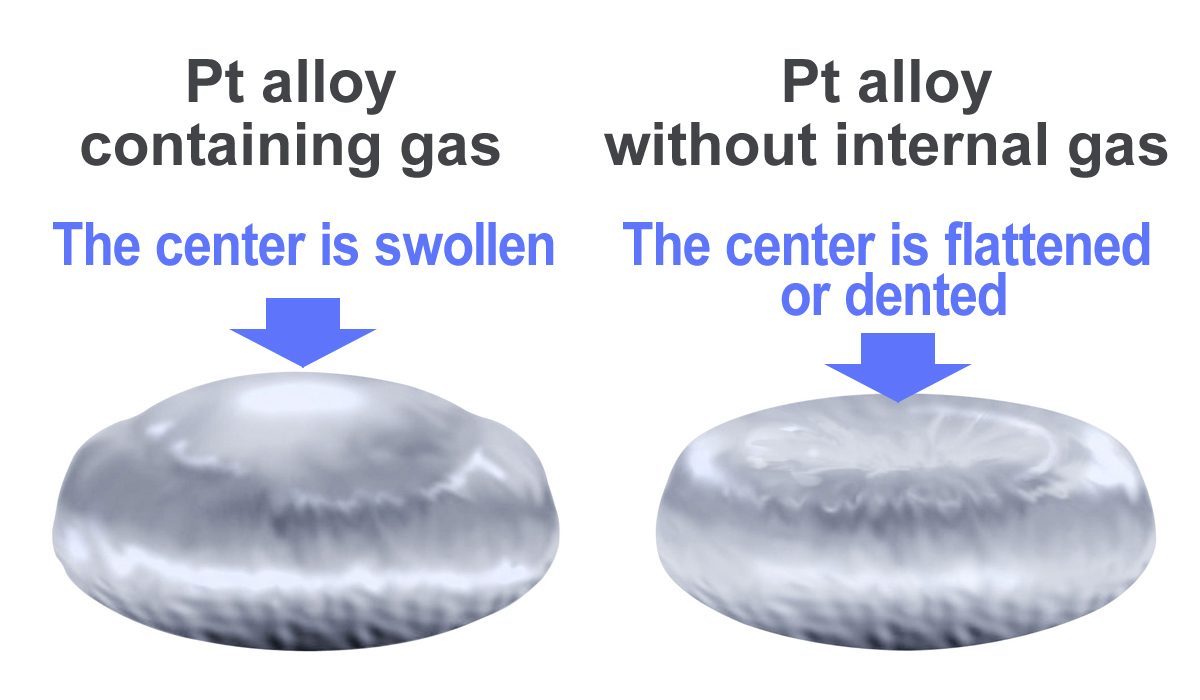

In the case of platinum, it can often be degassed by remelting it in a crucible. Let platinum solidify in a crucible after complete melting. Observe the top shape of the solidified platinum. If the center of the metal is bulge, the platinum alloy definitely has gas inclusion. Continue this heating and solidification process until the canter of the metal is flattened or dented. This confirmation work is highly recommended before casting.

CAUSE 2 / Gas generated by crucibles

Since the raw material of the crucible is natural, gas may be generated from a crucible depending on raw material.

Even if material is carbon or silica, it is recommended to replace a gas-producing crucible to a new one immediately.

-1024x597.jpg)

CAUSE 3 / Remaining gas due to lack of air permeability of casting molds

In vacuum suction casting and pressure casting other than centrifugal casting, part of gas in a mold is released out of a casting mold through gaps between the investment powder particles. If air permeability of a casting mold is obstructed, gas remaining in a casting mold may not be able to be discharged efficiently. This resulting in gas porosities or/and small dents appearing in castings.

It is necessary to check mixing ratio between powder / water or/and with binder.

For silica system investment powder, if powder is heated at a sintering temperature (900°C (1650F) or higher) for a long time (5 hours or longer), sintering of binder will proceed and air permeability of casting molds will be hindered.

CAUSE 4 / Gas entrainment due to turbulence

These porosities are mainly found in centrifugal casting.

It is a type of gas porosity and turbulent flow generated during casting traps gas inside a casting mold.

Substitution between pouring metal and internal gas is hindered and gas remains in vortex of melted

metal.

In a case of rings of jewelry, they are characterized by being continuous in the vertical direction form

the shoulder to the arm of a ring, as shown in fig.1.

Adjust the rotation speed of the centrifugal casting machine or change an attachment point of gate

sprue.

CAUSE 5 / Porosities by dendritic crystal

It is one of typical porosities that occurs when solidification of molten metal is completed in the state of dendrite (needle-like crystals like conifer leaves) due to insufficient temperature.

It occurs on entire surface layer of a cast but it is often difficult to repair the porosities because it is unpredictable how many cavities there are inside and how deep it is.

To solve this problem, metal temperature at casting or/and flask temperature should be increased.

Although the limiting temperature changes depending on original temperature that related to shape or/and volume of a cast , it is recommended to try increasing casting temperature in increments of 50C (120F).

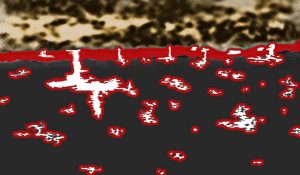

General porosity by dendritic crystal

Enlarged photo for dendrite

Cross-sectional image of porosities by dendric crystal

Solidification process leaves dendrites behind because melted metal completely solidifies before it fully fills cavities in a casting mold.

In other words, since spaces between the needle crystals exist as porosity, sizes, shape, depth and location of porosities are random.

Due to this reason, it is very difficult to completely repair those porosities.

CAURE 6 / Shrinkage porosities

As "directive solidification" cannot be secured when a casting solidifies, it occurs when supply of melted metal that matches volume of solidification shrinkage of the metal is obstructed.

Generally speaking, it occurs at thick parts of castings. Metals with high melting points and metals that shrink violently have a high risk of shrinkage porosity.

It is a porosity tend to be found in pressure casting.

But in any case, with directive solidification should be in mind, try to supply melted metal that compensates for metal shrinkage by adjusting attaching position and thickness of gate sprues.

For “directive solidification”, see (Link: "Cracks in Castings | Causes of Casting Defects and Countermeasures ④")

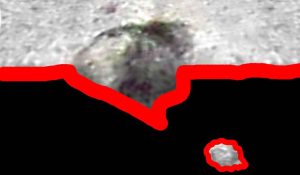

Shrinkage porosity that occurs with surface shrinkage

Shrinkage porosity on a Pt ring

Cross-sectional image of shrinkage porosities

It is created when directive solidification is not secured (appropriate thickness or/and length of gate sprue is not secured or attaching position of gate sprue to a cast is incorrect).

Also, it happens with casting metal temperature is being too high.

Shrinkage porosities are likely to occur even with metals that expand significantly such as platinum with ruthenium alloy.

The appearance differs depending on the alloy, but instead of appearing all over the casting like porosity by dendritic crystals, porosity may appear along with some dents, or multiple porosities may occur in some parts of the casting.

Summary of countermeasures for Porosity

Countermeasures for porosities are summarized blow.

To prevent hotspot that would create shrinkage, refer to “Hot Spots” where areas get hot in casting and its countermeasures”.

Check List

- Check flask temperature and metal casting temperature.

- Review if casting metal contains gas.

- Confirm air permeability of casting molds.

- Regulate rotation speed of the centrifugal casting machine.

- Test casting temperature in increments of 50°C.(120F) to find out proper casting temperature.

- Supply melted metal to compensate for shrinkage of casts with adjusting position, length and thickness of gate sprues.

There is not always one cause. Please review all the items again and see how they work.

When casting condition is desired to be changed, change it one by one.

If you change two conditions at one time, you will not be able to clearly find out an exact and direct cause for the casting error you have.

Author : M. Yoshida