★This column is a commentary on lost wax casting with a block molding method

This column has been presented by Yoshida Cast

Casting defects come in various forms, such as cracks in castings, surface roughness and porosity and so on.

Casting defects are classified into several types. And each of these has different causes.

In addition, since the casting process is diverse, the cause may not always be one, and most cases are complicated.

Typical failures are roughly classified into six categories.

Fourth, let's take a look at the causes and countermeasures for "Cracking Problems".

[toc]

What is "Cracking"?

This is a phenomenon in which cracks and fissures occur at the final solidification part of casts or/and at the tip of molten metal during solidification.

In a case of jewelry such as rings with a high copper content like pink gold, red gold, etc., cracks will not be seen immediately after casting. However, cracks may occur when the metal is reheated to resize those rings may also occur.

Why cracking of casts take place. And what is countermeasure.

The causes of cracking in castings can be broadly classified into three categories. The causes and countermeasures are independently introduced in this column.

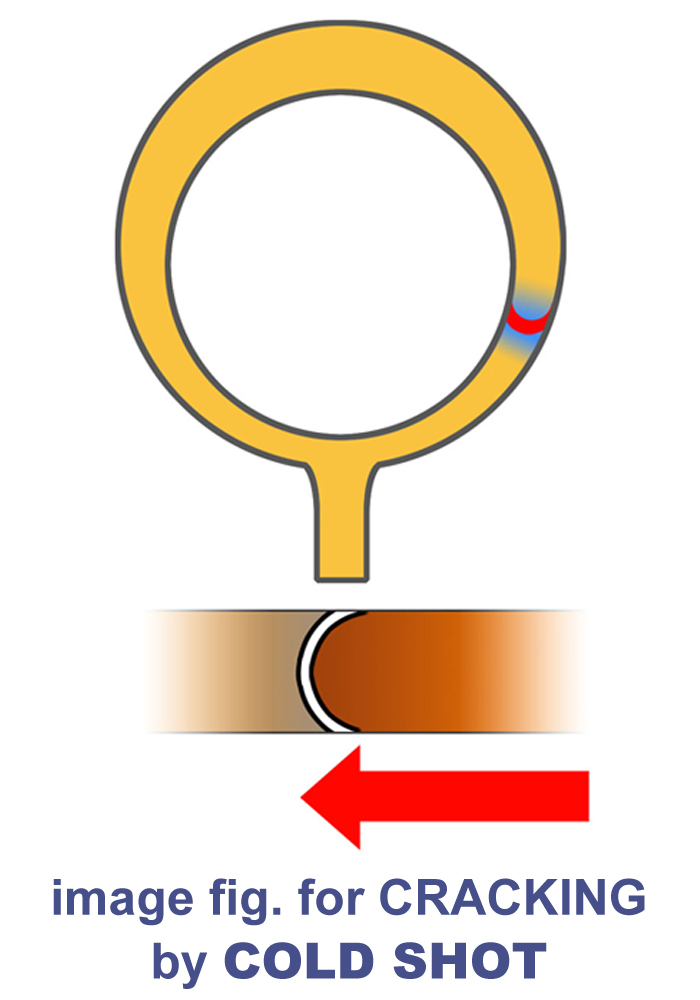

CAUSE 1 / Cracking due to Cold Shot

In case if casting metal temperature too low, At the point where melted metal flowing from multiple directions intersects during casting, a boundary occurs at the confluence surface due to insufficient temperature when the tip of the melted metal joins that comes from the other side.

Typical shape is one end is rounded and the other is recessed.

Increase flask temperature or/and casting temperature of casting metal to make solidification time delay.

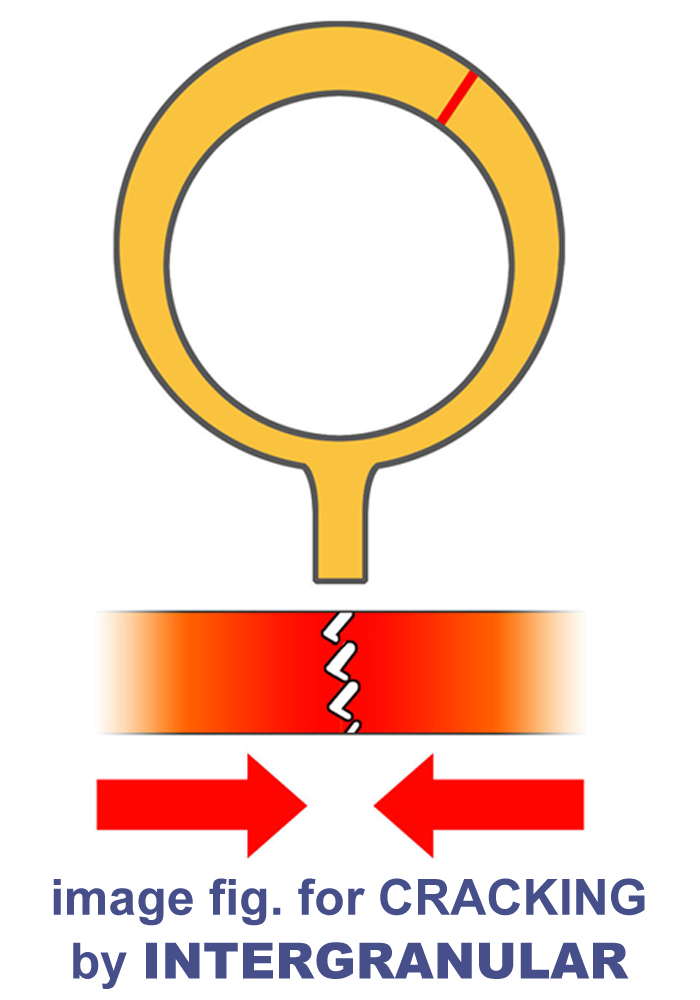

CAUSE 2 / Intergranular Cracking (including brittleness)

In polycrystalline metals (alloys), gases and foreign substances (intermetallic compounds and oxides) are confined between crystal grains.

In this case, since adhesion between crystals is low, cracks occur in places where internal gas and impurities tend to accumulate, such as places where shrinkage stress concentrates during solidification and shrinkage, and places where molten metal merges and coalesces.

Change the confluence point of the melted metal with installing air vents for venting gas, changing the thickness of runners or ingates, or changing the angle of attached runners.

In case of pink gold and red gold for example, cast flasks should be immediately quinch to cool down after casting in order to reduce the size of the crystal grains as much as possible.

This prevents grain boundary cracking during secondary heating.

In addition, depending on the type of alloy, the crystalline structure may change during the solidification process (slow cooling, rapid cooling, etc.) after casting, causing the metal to become brittle.

In such cases, the cooling method should be changed accordingly, or annealing or tempering should be performed.

For alloys with solid solution limit, solution treatment is performed after casting.

.jpg)

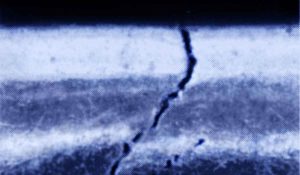

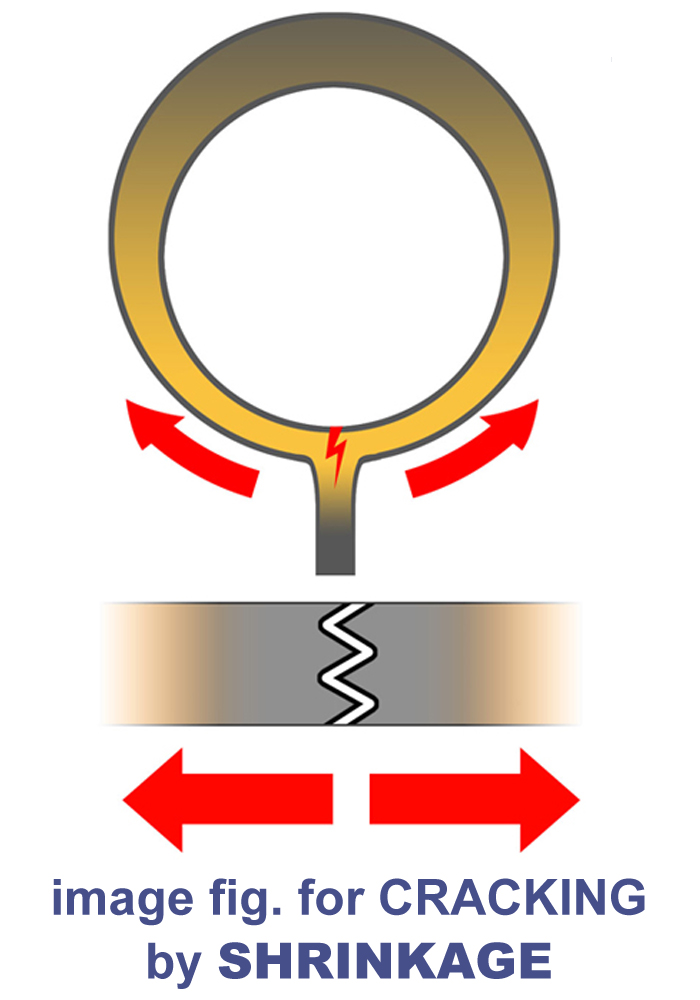

CAUSE 3 / Shrinkage Cracking

This is a phenomenon in which directive solidification is not ensured.

Solidified part breaks as if it were torn due to the stress caused by solidification shrinkage with

a time-lag.

What is directive solidification?

In general, objects (substances) expand as its temperature rises.

Metals are no exception, especially metals during casting expand greatly because they are melted.

However, when the state (phase) of the metal goes from melting to solidifying, it shrinks.

*Some metals shrink when the temperature rises.

In casting, this property should be taken into consideration. In other words, it is ideal that melted metal should be solidify in order from the tip of casting in order to keep supplying melting metal until completion of entire solidification.

This is called directive solidification.

In order to perform this directive solidification, thickness, length, and location of gate sprues are appropriately determined.

.jpg)

No directional solidification adapted directional solidification

Summary of Casting Cracking

Countermeasures for cracking problems are summarized blow.

Check List

- Increase casting temperature of both casting molds and casting metal in order to lengthen solidification time.

- Attach air-vents for gas release.

- Change thickness, length, installation location and angle of gate sprues.

- In case of casting for pink gold or red gold, let casting molds cool down immediately after casting in order to shorten solidification time. (to prevent crystal growth)

There is not always one cause. Please review all the items again and see how they work.

When casting condition is desired to be changed, change it one by one.

If you change two conditions at one time, you will not be able to clearly find out an exact and direct cause for the casting error you have.

Author : M. Yoshida