★This column is a commentary on lost wax casting with a block molding method

This column has been presented by Yoshida Cast

Sprue system is one of the most important casting techniques.

Ensuring "directive solidification" when the molten metal is poured into cavity inside a casting mold, "suppressing turbulence" and "reducing hotspots" of molten metal during casting, taking into consideration the static casting theory.

It is a measure to reduce casting defects from the viewpoint of melting metal flow and metal solidification by examining the gas replacement action.

In this column, basic way to prevent turbulence of casting metal is explained.

[toc]

Turbulent flow generated by different cavity configurations

As discussed in a column of "How casting metal flow", it is necessary to consider turbulent flow of molten metal in addition to characteristics of the metal when actually casting.

Turbulent flow of molten metal always occurs at junctions of surfaces with different angles, angular surfaces or lines, places where lines intersect or diverge, and at passage points from wide areas to narrow areas or from narrow areas to wide areas.

Since turbulent flow of molten metal can cause casting defects, it is necessary to consider sprue system that prevents turbulent flow at product designing process.

Since turbulent flow of molten metal is closely related to hotspots, methods for sprue system for preventing turbulent flow is similar to preventing hotspots.

In this column, we will discuss turbulent flow.

Hotspot suppression is discussed in detail in a separate article.

Turbulence generated in center sprues

In most cases, molten metal received at a pouring (inlet) into a center sprue with a swirling motion, although degree varies depending on the size of a casting mold and a casting method to be used.

The preventive measures introduced here are those used in gravity casting, such as sand casting. Although the block mold method is subject to restrictions such as casting mold size, basic concepts are introduced here.

Generation of turbulence with A straight center sprue

Prevention of turbulence with a will (reservoir) method

Note: Turbulent flow is generated at the locations marked X in above figure.

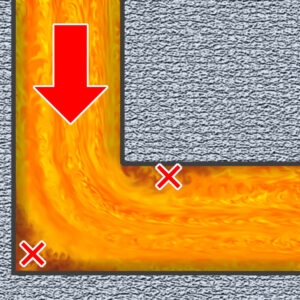

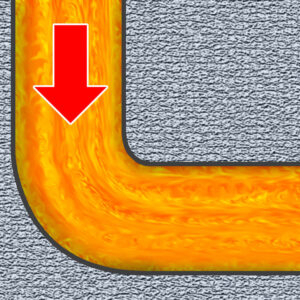

Turbulent flow at L-shape corners

When molten metal passes through a curved or/and vend corner, turbulent flow occurs at the corner.

It is desirable to make the corners as round as well as possible.

Turbulent flow at a L-shape corner

A measure to prevent turbulence at L-shape cavity

Note: Turbulent flow is generated at the locations marked X in above figure.

Turbulent flow at T-shape intersection

These are turbulent flows that occur in cavities such as T or Y-intersection cavities and how to prevent them.

Although the following methods may not always be possible due to design constraints or dimensional accuracy, it is necessary to design to prevent turbulence as much as possible.

Turbulent flow at a T-intersection

A measure to prevent turbulence at T-intersection cavity

Note: Turbulent flow is generated at the locations marked X in above figure.

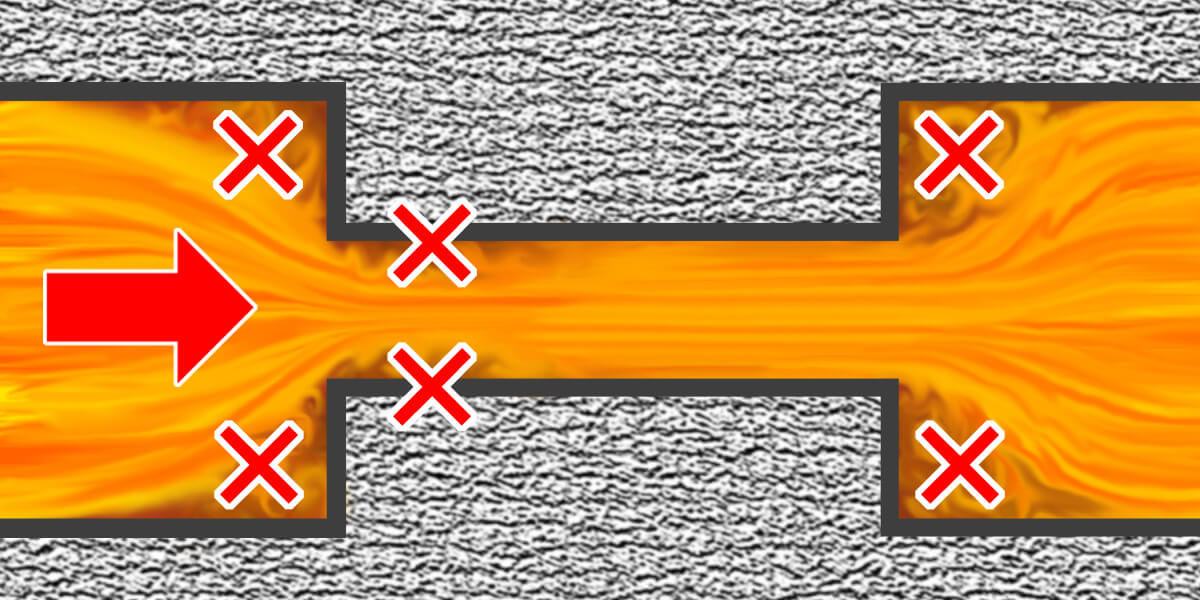

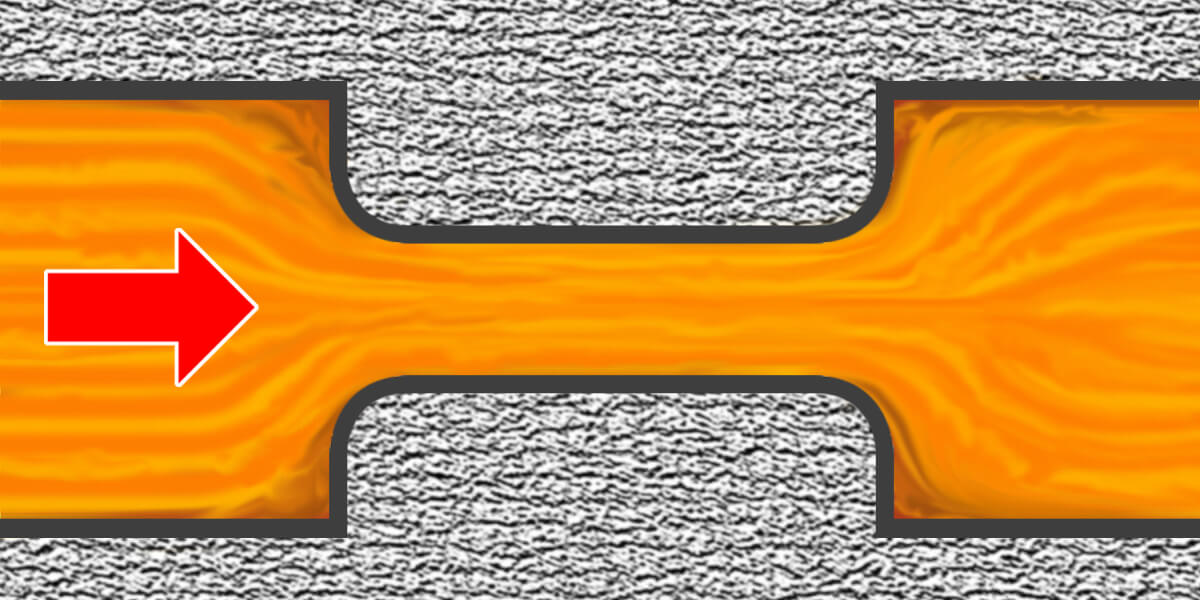

Turbulent flow at concave shape

Turbulence also occurs when molten metal passes through thin (narrow) areas as shown in the figure below.

Turbulent flow at a concave shape

A measure to prevent turbulence at concave

shape cavity

Note: Turbulent flow is generated at the locations marked X in above figure.

Author : M. Yoshida