★This column is a commentary on lost wax casting with a block molding method

This column has been presented by Yoshida Cast

“Reservoir” is a lump of melted metal that is set up to delay time of solidification.

One of the essential conditions for gate sprue (ingate) is that " melting metal can be supplied until a cast (product part) completes solidification."

Other purpose for installing reservoir is to supply extra melting metal that is insufficient due to solidification shrinkage at a specific location.

[toc]

Conditions for "reservoir"

Reservoir at gate sprue (ingate)

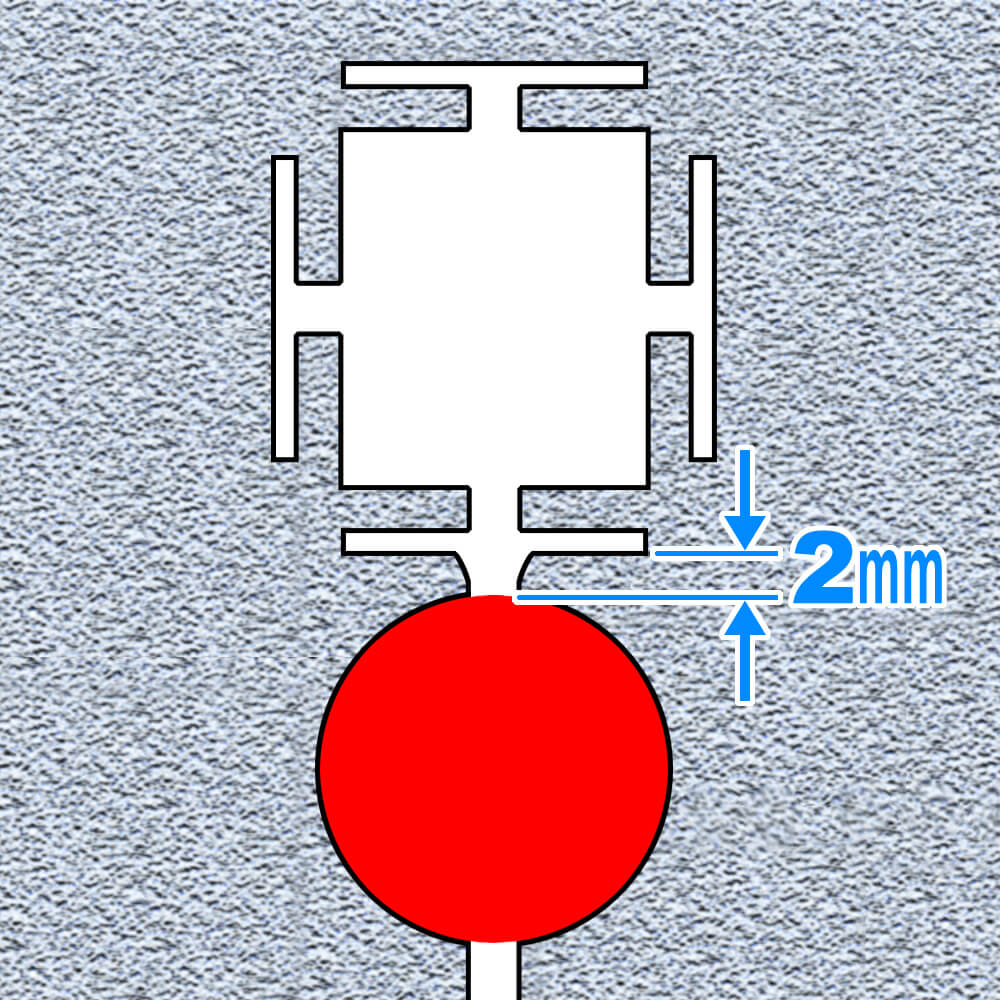

| CONDITIONS FOR RESERVOIR ON GATE SPRUE | |

| SHAPE | Spherical |

| VOLUME | Same as volume of a cast or cast (product) part around place ingate has been attached |

| AREA | 2 mm (0.1 in) or less from an ingate |

| CAUTION | No turbulent flow of melting metal flowing into a cast (product). |

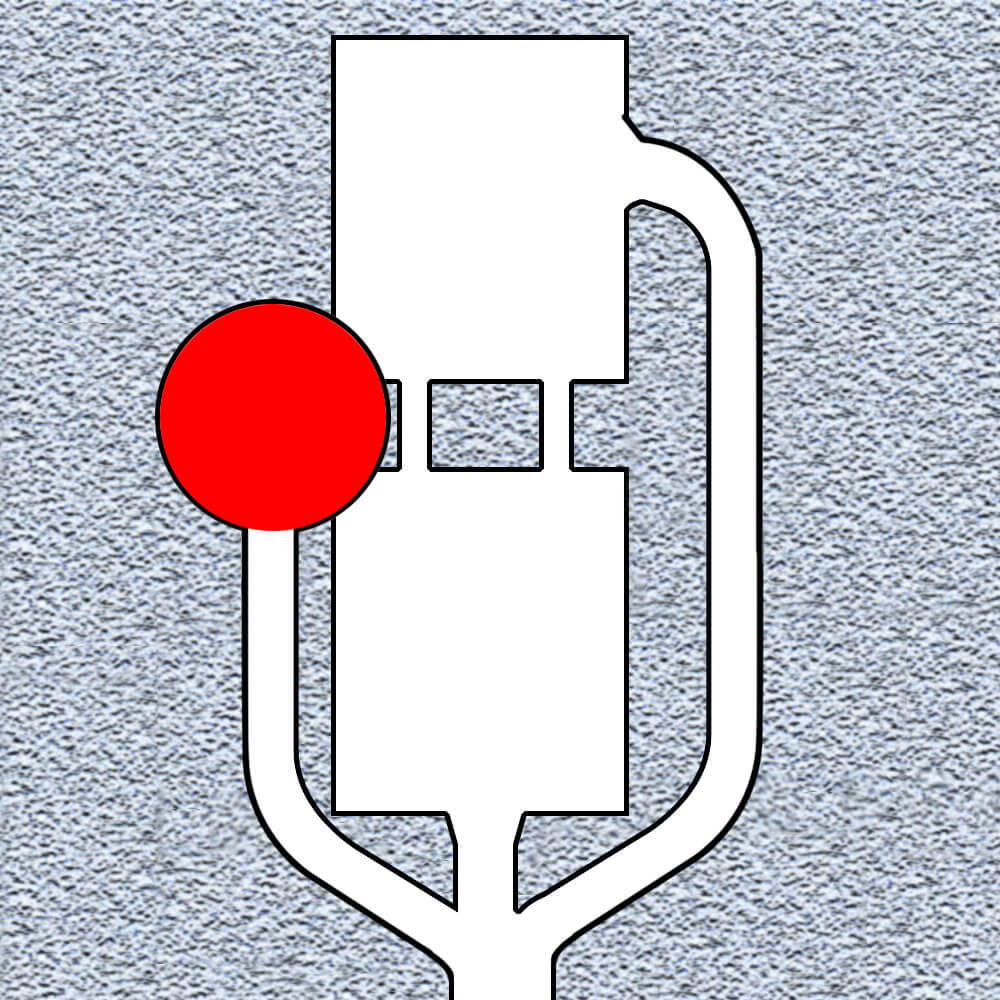

Independently mounted reservoir

CONDITIONS FOR INDEPENDENTLY MOUNTED RESERVOIR

SHAPE Spherical VOLUME Same as volume as a part around where solidification speed slow down. AREA 2 mm (0.1 in) or less from an ingate

Where to install and appropriate volume for reservoir

Generally speaking, a reservoir is usually installed just before the joint between a gate sprue and a cast (product). Reservoir needs to be solidified slower than cast. So, make it larger than the volume of product part.

The shape is generally spherical. If the shape is other than a sphere, surface area relative to the volume will be large and cooling time will be faster.

As a matter of fact, solidification will be faster.

In order to ensure partial directive solidification, a reservoir should be installed at places other than the runner if necessary.

Install a reservoir near the place where solidification time is desired to slow down. Distance between a cast and a metal basin should be within 2 mm (0.1 in) or less.

Auther : M.Yoshida