★This column is a commentary on lost wax casting with a block molding method

This column has been presented by Yoshida Cast

Sprue system is one of the most important casting techniques.

Ensuring "directive solidification" when the molten metal is poured into cavity inside a casting mold, "suppressing turbulence" and "reducing hot spots" of molten metal during casting, taking into consideration the static casting theory.

It is a measure to reduce casting defects from the viewpoint of melting metal flow and metal solidification by examining the gas replacement action.

How to install sprue is one of the most important basics to prevent casting failure.

Thickness and angle of gate sprues, attaching position of sprue on products, and shapes of wax trees (casting trees) must be appropriately changed for difference of casting methods, metal solidification time, metal viscosity, and shape of casting products.

In this column, 3 principles of wax tree assembly that must be taken into consideration when wax tree spruing is done.

[toc]

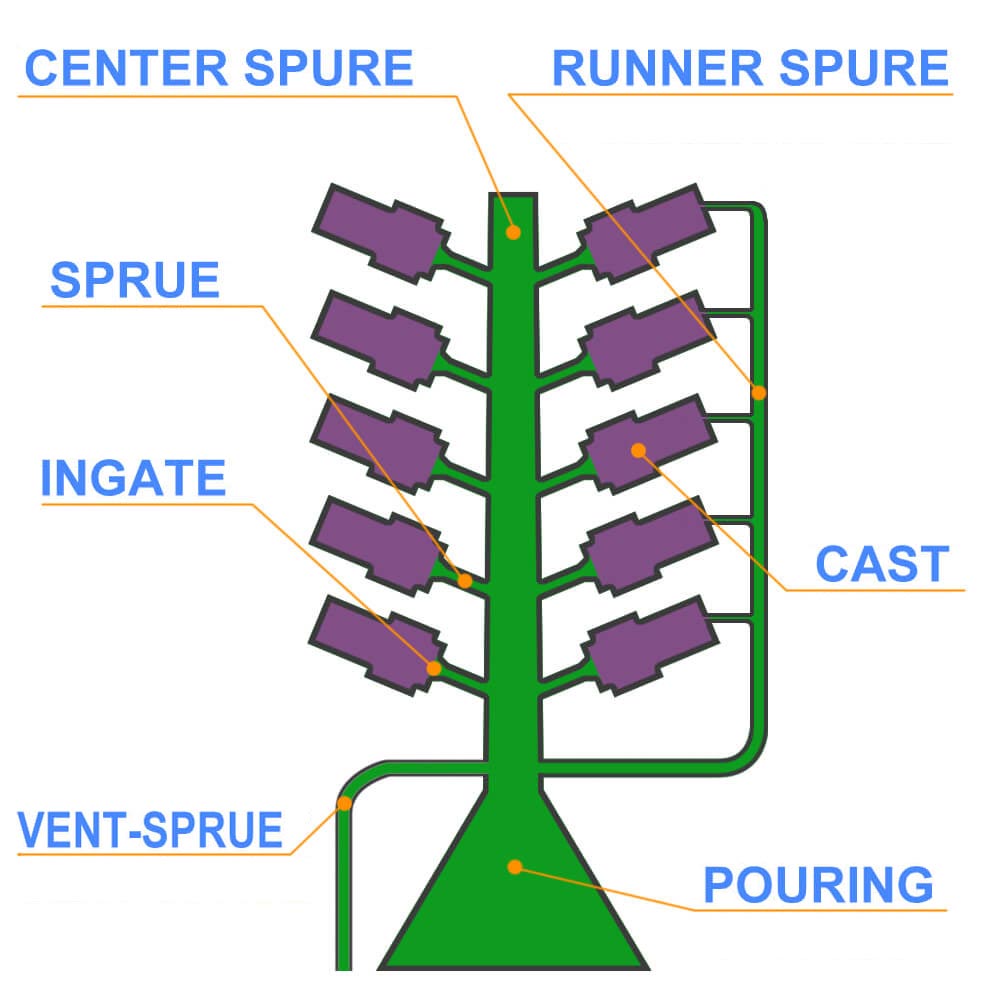

Typical shape of wax tree and name of each part

First of all, part name of wax tree is explained below.

Shape of a casting tree differs depending on a casting method and size of product to be cast, but the name of each part is the same even if the shape is different.

The name of each part of the casting tree changes slightly when casting technique changes, such as ceramic shell method and sand casting.

In block mold method in lost wax casting, those above names are ordinarily being used.

In lost wax casting, a casting tree is consisted with following parts such as "Center sprue (down sprue / main sprue)", ‘Pouring (becomes a button)”, Sprue (gate sprue)” Ingate and “Runner sprue”.

Runner sprues for vending gas are called “Vent-sprue or Air-venting sprue”

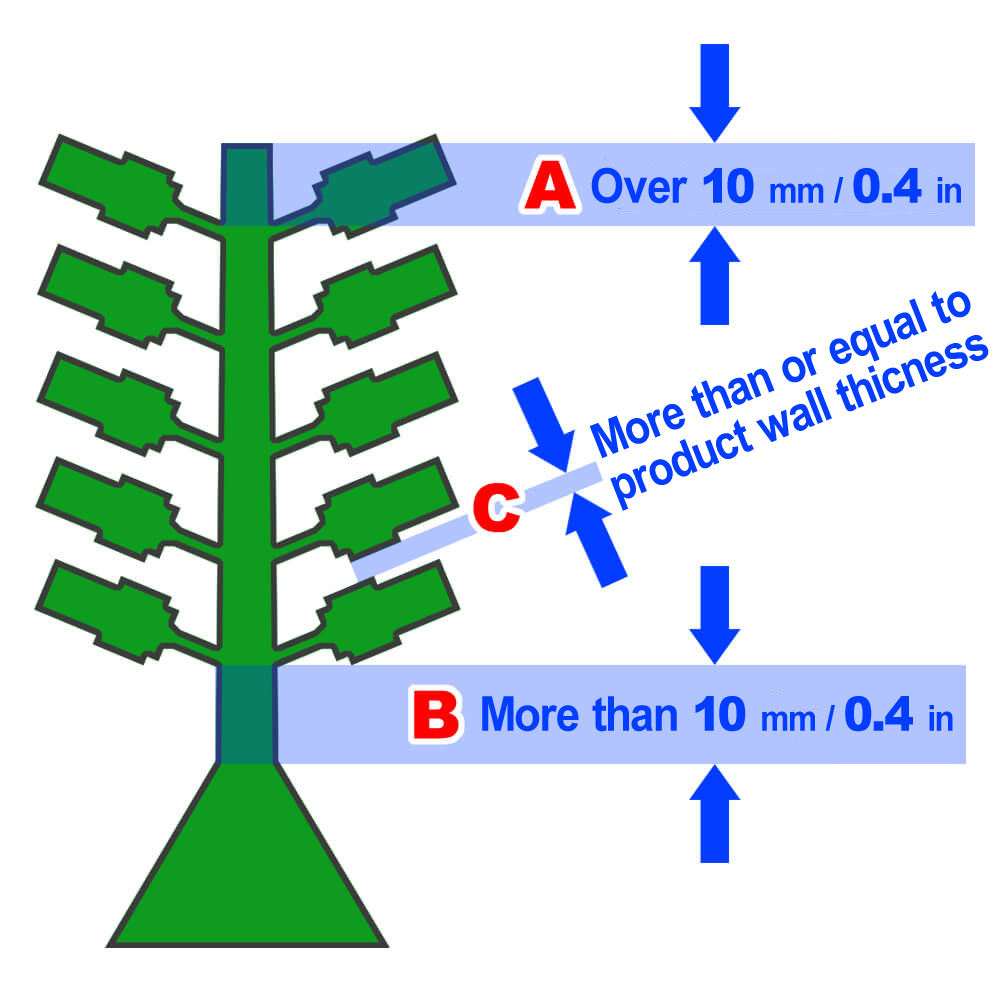

Basic 3 rules of wax tree

There are basic rules that must be followed when assemble a wax tree.

This is a case for wax trees with a center sprue

A Avoid attaching products to approximately 1 cm from the tip of the wax tree

Molten metal that is poured from a pouring first descends center sprue and reaches the tip of wax tree. The area around this tip becomes a hot spot.

If there is a product around this area, surface of those casts (products) will be roughened by heat.

In addition, gas contained in the molten metal first reaches the tip. This may cause gas porosities.

Therefore, do not attach the product to the tip of the wax tree.

B Avoid attaching products to approximately 1 cm above a pouring (inlet)

Molten metal is supplied from tip area of a wax tree and finally fills area around a pouring (button).

Since gas generated during solidification rises to the button area, a large amount of gas will eventually gather near the button.

Gas porosities often occur at products near this area.

C The distance between products should be greater than or equal to the wall thickness of products

It is desirable that distance between products each other should be at least the same as wall thickness of products next to. This is because directive solidification may not be ensured if the products are too close together.

Needless to say, there are cases when products are unnecessarily too close to each other, the wall may be broken by inflow pressure of molten metal during casting. So, it should not be too close and ensure necessary strength of walls in a casting mold.

However, there may be a case it is difficult to ensure directive solidification depending on shape of cast (product).

In this case, in order to slow down solidification speed, castings (products) are intentionally brought closer to each other to create an effect of "molten metal basin (as heat reservoirs)".

Shapes of pourings (inlets)

There are advantages and disadvantages due to the difference in shape of pourings. This is also related to the difference in the method of pouring melted metal into a casting mold (flask)

Typical shapes are classified into 3 categories and consider each of them.

Small conical shape

If amount of melting metal in a crucible is large and at the same time thickness of sprue such as center sprue is thinner than amount of pouring molten metal, the mold cannot swallow molten metal in short time and it will spill out from a pouring.

Generally speaking, when size of button is small, directive solidification for entire casting tree cannot be ensured.

Thus, basically a casting tree with a small pouring (less quantity of button) should be avoided.

| ADVANTAGE | Reduction of metal costs Good for Centrifugal casting |

| DISADVANTAGE | Higher possibility of casting defects |

Large conical shape

This is one of the most common shapes.

Molten metal that hits inner wall of the pouring tends to go downward. This making it difficult for molten metal to pop out of the pouring.

However, it is a prerequisite that thickness of a sprue directly under the pouring such as center sprue should be sufficiently thick.

| ADVANTAGE | Hard to spill out Good for fast-solidifying metals |

| DISADVANTAGE | Bad for slow-solidifying metals For metals with large shrinkage or/and long time to solidification, it may not be possible to secure sufficient supply of melting metal a wax tree. |

Bowl shape (Curved cone)

Effective in case the volume of slow solidifying metal or product is large.

However, if volume of this pouring is smaller than the amount of molten metal to be cast or in centrifugal casting with high spin, there is a risk that molten metal received at the bottom of the pouring will swirl. In this case, casting metal might spit out from the pouring.

| ADVANTAGE | Good for metals with large shrinkage or/and slow solidification |

| DISADVANTAGE | Bad for centrifugal casting and crucible tilting method In casting other than the bottom pouring method, melted metal may swirl in the inlet or metal that doesn't flow directly into the center sprue may be bounced out of the inlet. |

How to set up a wax tree for each casting method

Shape and method of wax tree selection differs depending on casting conditions.

Each is described in a separate column.

Author : M. Yoshida